Satisfying Your Curiosity About 3D Printing

HISTORY OF 3D PRINTING

Although you might think 3D printing is a new technology, it has been around for quite a while. The journey of 3D printing began when Hideo Kodama published a paper in 1981 describing a rapid-prototyping system which made use of photopolymers, an acrylic-based material. When a UV laser beam hits a liquid photopolymer, it turns into a solid.

Three years later, Charles Hull invented stereolithography. This machine lets designers make digital models and transform them to print something tangible. The secret of stereolithography lies in its use of the previously studied photopolymers to create a seemingly endless array of printed products.

This technology became a huge draw for inventors because it gave them the luxury to test designs without spending too much on production. In 1992, Charles Hull’s company created the first-ever stereolithographic apparatus machine (SLA). Shortly after, another company produced the Selective Laser Sintering Machine (SLS) which sprouts laser in powder, instead of traditional liquids. It was time for big business to start to pay attention and work with top-rated graduate programs to deliver on the promise of 3D print technology.

This type of printing evolved in the late 1990s, blossoming in the medical field. It was during this time when the first 3D-printed organ, a synthetic bladder, was implanted into a human. Before it was implanted into the patient, the 3D-printed bladder was first coated with the cells of human patients. Other breakthroughs in the medical field using 3D printing also includes prosthetic limbs, stabilizing and immobilizing injured limbs, improved blood vessels, and miniature kidneys.

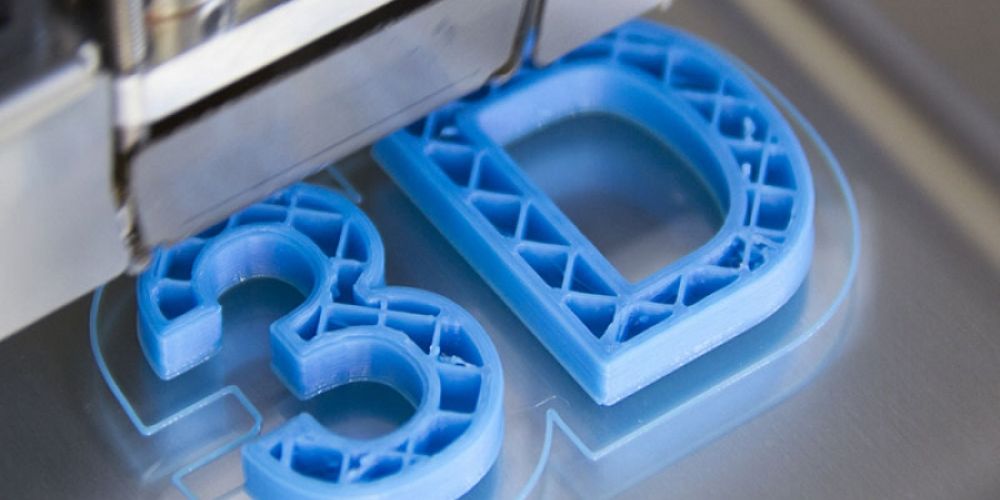

HOW DOES IT WORK

To make something using 3D printing, designers need to prepare a blueprint of the object they want to create. This can be done using modeling software.

Some printers have a bioplastic spool which functions as a string. After the printer receives the design, it pulls the spool through a tube. The string is then melted and deposited to a plate where it becomes instantly cooled. To create the object, the printer will add a layer at a time until the complete structure is formed.

UPSIDES OF 3D PRINTING

Without a doubt, 3D printing has helped revolutionize many fields today. 3D printing is a great equalizer. It’s accessible to almost everyone, not restricted to some revered elite. Here’s a look at some of its prominent advantages:

1. 3D Can Be Affordable

One of the major advantages of 3D printing is that it allows designers to make complex shapes which cannot be easily produced by other methods. And this unique manufacturing approach is not accompanied by any additional cost above the expense of the printer itself and its materials.

Additionally, 3D printing can help startups manufacture products and keep overhead low. This method of printing can make thousands of identical parts without needing any specialized tools. Its cost depends simply on the material it uses and the length of time it takes for the machine to make an item.

2. Convenient Customization

Manufacturers sell products in standardized sizes – this has always been the case for tools, clothes, and even food. Unlike other methods, 3D printing allows customization to augment standardization with flexible, adaptable products.

To change a product, the manufacturer needs only to alter the digital model. Each following item will be printed according to the updated blueprint with the specific needs of individual consumers without increasing manufacturing costs.

3. Wide Range of Materials

Plastics are currently the most common material used in 3D-print technology, however, the use of other materials has resulted in many amazing products. There is a growing trend towards using recycled materials with your 3D printer. Now, 3D printing is even employed to ‘make’ food. A simple search yields a variety of restaurants that serve intricate snacks that were made by a 3D printer.

Additionally, countless items can be manufactured with components tailored to their intended use. 3D materials can be heat resistant, stiff, biocompatible, and have high durability. Furthermore, using composites has become common in 3D printing. Composites can be supplemented with materials such as carbon particles, ceramic or wood.

4. Quick Prototype Turnaround

No other prototype technology can compete with the speed and cost of 3D printers. It enables complex parts to be printed overnight. Even large orders can be done in just a couple of days with very little human intervention. Because of this, product prototypes which usually take months to be developed and tested can now be ready in just a matter of weeks.

3D PRINTING TODAY

Today, 3D printing technology offers amazing opportunity and is now more accurate than ever. Its price has also decreased dramatically. Furthermore, designers are not constrained to only using plastic. People can even use gold or silver! However, the use of 3D printing extends beyond fine jewelry and trinkets. It is also used for aircraft components, automotive parts, and affordable housing in third world countries, and seems limited only by its owners’ imagination.

In the medical field, doctors and scientists are testing 3D printing applications for regenerative medicine. Using the cells of a patient, doctors can make body parts such as a nose or ears, or build 3D-printed scaffolding to support cells that need repair. It has also been tested for organ transplants and remains a potentially viable life-saving solution.

THE FUTURE OF 3D PRINTING

Without question, the potential of 3D printing and how we use it is practically limitless. It has the potential to save our seas through artificial coral reef production and can even help put manufacturing back in the hands of those who stand to benefit most. As the technology becomes more accessible by people around the world, it could easily help supply necessary goods to those who are marginalized. So yes: herein lies immense potential, but it is paired with significant responsibility to ensure that the technology is used in a way that remains considerate of the planet and the life it supports.